6 Keys to Successful Q4 Holiday Season Fulfillment

Hard to believe, but we’re more than halfway through 2019. With so many moving pieces to align in your supply chain, it’s critical to finalize your Q4 strategy now to ensure smooth fulfillment operations in the busy months ahead.

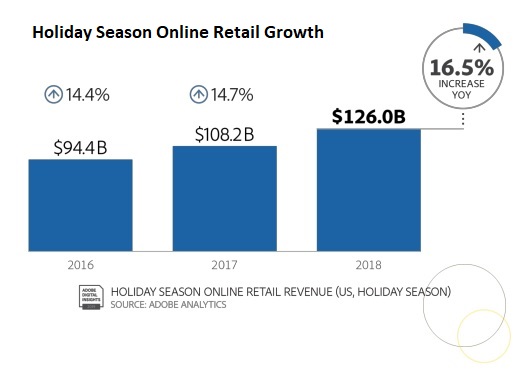

eCommerce Continues to Surge

Year over year, ecommerce sales continue to surge. Adobe Analytics reported that 2018 holiday ecommerce sales totaled a whopping $126 billion, a 16.5% increase from 2017. For some brands, that considerable growth brought about challenges.

The most common ecommerce issues that brands faced last year included:

- Inaccurate orders

- Delayed shipments

- Customer service issues

- Inefficient returns processing

- Uncontrollable cost management

If you’re not prepared for a spike in order activity, which for some brands will start as early as August, your fulfillment operations and customer satisfaction will suffer.

6 Keys to Successful Q4 Holiday Season Fulfillment

To meet the demands of Q4 and ensure you come out strong on the other side, focus on these 6 key areas of planning:

#1 – Staffing

Having sufficient staff to handle peak order volume is perhaps the biggest challenge for most businesses. And it’s no wonder – fulfillment consultancy F. Curtis Barry and Company shares that during the peak holiday season, some of the clients they work with have a 10:1 or higher order ratio when comparing their peak order weeks to an average week.

To ensure adequate manpower during peak season, some businesses choose to staff up. This could mean adding overtime or on-call hours for current staff. Or, it could mean hiring seasonal workers.

To help attract more hires, some companies are also offering flex hours that allow workers to take on part-time or weekend-only shifts. Many companies will also incentivize with higher hourly rates based on above-average quality/productivity performance.

Companies that plan to onboard new seasonal workers should do so in Q3 to allow for enough time for training and ramp up. Staff should also be cross-trained when possible, so workers can take on different responsibilities as needed.

#2 – Fulfillment Automation

While sufficient staffing is still a critical part of a successful Q4, more companies are introducing automation into their supply chain where they can, so they don’t need to rely as much on hiring – especially in today’s tight labor market.

Automation not only reduces labor overhead and a company’s reliance on manpower, but it also allows for easier resource scalability based on clients’ forecasts.

Automation technologies are evolving and becoming more sophisticated every year. Some of today’s most popular automation solutions include automatic sortation equipment at picking and packing areas; auto-bagging equipment; auto-labeling equipment; and interim conveyor systems that can help with increased order processing.

In addition to using automation, companies can also get creative elsewhere in their fulfillment operations to gain efficiencies. Re-slotting, or moving top-selling SKUs to the close pick locations to improve pick time, is just one example.

#3 – Forecasting

Understanding what your projections will be for Q4 is critical for holiday season fulfillment success. Using historical data from throughout the year, along with historical data trends from prior holiday seasons, will help you develop more accurate order forecasts.

When the heaviest order period hits – typically from Black Friday all the way through Christmas Eve – start to create weekly forecasts for each channel you’re operating in.

At PFC, we’ll conduct weekly operations calls with clients during Q4 to ensure we’re working from the most recent data available, so we’re equipped to handle the demands this extra-busy time brings.

Frequent forecasting also helps to create a solid line of communication with all parties and creates transparency.

#4 – Shipping

Fast shipping continues to be the top priority for businesses but it’s even more critical to deliver speed during the busier Q4 months.

In 2018, the big three carriers – UPS, FedEx and the U.S. Postal Service – all posted peak season on-time delivery rates of above 97%, which was a slight increase from 2017. This is good news for both businesses and consumers.

Here’s what the big carriers are saying about their 2019 peak season operations:

- The U.S. Postal Service anticipates delivering over 900 million packages between Thanksgiving and New Year’s Day.

- UPS is working on a super hub in Atlanta that will have the capacity to sort 100,000 packages per hour along with 22 automated facilities around the globe. As international shipping continues to grow, we can likely expect more international facilities from all carriers.

- FedEx announced last month they’re transitioning to a 7-day residential delivery schedule starting this fall, which will extend to most of the U.S. in January.

For businesses, the promise of faster package processing and shipping is all good news. But the reality is that shipping costs continue to rise for all carriers, year over year. And dimensional weight pricing (DIM) continues to change. Click here to see the DIM weight price changes from USPS, which took effect June 23.

Companies need to leverage everything they can do get the fastest and most economical shipping methods available. And when it comes to Q4 shipping, understanding the seasonal carrier surcharges and holiday package delivery cutoff dates is critical.

Cutoff dates from the big 3 carriers will be announced by the end of October. We’ll share the details here when we have them.

#5 – Quality

When delivering a positive brand experience to your customers, consistency in quality is of high importance. This is especially true during Q4 when you’re fulfilling higher order volume – often times for customers who might be doing business with you for the very first time.

Focus on quality across all aspects of your fulfillment operations – from hiring and training and forecasting and analytics.

#6 – 3PL Support

Sometimes the best course of action for effectively managing your peak season is to get expert third-party help. A 3PL can be an incredibly valuable partner. Their state-of-the-art facilities and technologies, staffing resources, and tight network of suppliers and carriers can result in big cost savings and optimized performance for your 4Q peak season.

About Promotions Fulfillment Center

At PFC, our clients’ success is our #1 priority. Since 1974, our team has delivered outstanding quantifiable results, with turnkey solutions in ecommerce & web fulfillment, and contact center services – all backed by leading technology. Retailers and ecommerce brands that partner with PFC have historically achieved considerable cost savings in excess of 35% and have significantly improved their program ROI.

Learn more about PFC’s eCommerce fulfillment solutions or email us at info@pfcfulfills.com.