Best Practices – Inventory Management

The growth of omnichannel shopping transactions has created the need for increased inventory control as well as flexible, faster and more accurate order fulfillment. These factors contribute to the need to convert distribution warehouses into dynamic, integrated and scalable product fulfillment centers.

Today’s product fulfillment professionals face a series of significant changes in the way warehouses, distribution centers and their entire supply chain operates. The demand for integrated communication and transparency throughout the fulfillment process will be key to streamlining the inventory management processes.

Fulfillment centers face a wide-range of challenges in the new economy including:

- Customer demand for personalization driving up the number of SKUs

- Increased inventory visibility, accuracy and efficiency

- New regulations calling for more accurate product tracking and tracing

- Push for more efficient and cost effective labor management

Issues such as these create unnecessary burden for product and ecommerce fulfillment providers including preventable excess costs and poor customer satisfaction. Below are a few best practices to help get your product and ecommerce fulfillment center truly optimized to meet the demands of today’s consumers and retailers.

Getting Started

Your first step is to conduct an audit of where you are and what steps need to be taken to achieve your goals. Determine what inventory you have, where it is located and, most importantly, how often it is used (velocity).

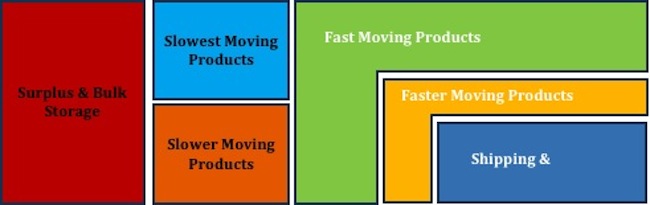

Once you determine your inventory velocity, you can begin to organize your product in a way that provides maximum efficiency and minimum amount of time spent in the pick, pack and ship process. Below is an example simple floor plan to help product and ecommerce fulfillment centers streamline inventory management.

To stock or not to stock?

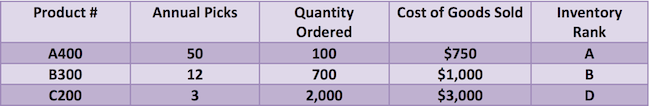

There are times when it may not make sense to stock a product. As an example, if an item is picked only five times a year, the cost of storage can be eliminated by drop shipping from the manufacturer. By recording the number of times a product is picked, you can determine the value of the space where the inventory resides. Consider this example below:

While the third product is the highest revenue draw, the fact that only three items were picked demonstrates the need to either eliminate inventory or consider alternative methods. While the first product is not a high revenue generator, it is a product that is in demand and therefore should be restocked frequently to avoid a backorder situation.

The traditional way of storing products is to group like items or brands together. But an intelligent inventory management system eliminates the need to store client products within close proximity. Configuring your inventory from highest picked to least picked will save you both time and money.

Setting the Bar

Once you determine how your inventory will be organized, the next step is to set min/max levels for each product. There are several factors to take into consideration when setting min/max levels for inventory.

- What is the item’s annual turnover?

- What order quantity is best to maximize both cost savings and storage efficiency?

- If you have multiple facility locations, what is the best way to divide the inventory?

- What is the vendor/manufacturer turn time?

After these issues are addressed, the next step is to automate your processes to ensure all parties receive timely communications relative to inventory control. Be sure to have an escalation process in place, so if your first point of contact cannot be reached then a second and third party is automatically notified. This will ensure a closed-loop process for inventory management.

- If you budget for demand and inventory, you establish goals for item level demand planning and monthly inventory scheduling. Ignore these controls and inventory levels will be much too high.

- Bowen Smith, SVP, Sales & Marketing

Multi-Channel Considerations

Products that are distributed to retailers have a completely different set of rules and standards compared to a direct to end user model, which is why it is critical for product and ecommerce fulfillment centers to manage inventory such as lot codes and expiration dates.

Speed to market is often the determining factor when it comes to expiration dates. Products that are shipped to retailers often have a longer shelf life than one that is shipped direct to consumer. Having the ability to manage both retail and consumer inventory helps with front-end purchasing as well as back-end distribution.

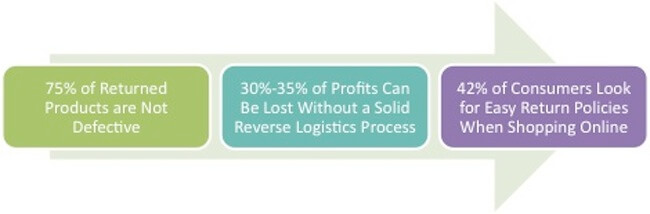

Get a Handle on Returns

Returned products are as important to the lifecycle of a product as when it was originally shipped. SOPs should be established for each client relative to its return processes. Whether the product is returned to stock, recycled, refurbished or discarded, the following steps should be taken to ensure returned items do not become a permanent part of the warehouse graveyard:

- Conduct a thorough inspection of returned inventory for reallocation or disposal.

- Reserve a space for quarantined items, but have a process to deal with them quickly.

- Provide automated product reshipment process.

- Provide transmission of returns data file.

Clients may also request a QA audit on returned products to help determine the root cause of the problem at the manufacturing level and quarterly analysis. This type of value-added service will help make your product and ecommerce fulfillment center a dynamic partner for returns management.

Source: Operations & Fulfillment

When choosing a product and ecommerce fulfillment partner, be sure you select someone that can confidently sustain your business model. When speaking with potential partners, be sure to ask how they manage their inventory to uncover whether they are operating at maximum efficiency and have processes in place to ensure seamless, integrated and transparent processes.

About PFC Fulfillment

At PFC, our clients’ success is our number one priority. Since 1974, PFC has delivered outstanding results, with turnkey solutions in fulfillment, e-commerce, and contact center – all backed by leading technology. Brands who partner with PFC have historically achieved considerable cost savings in excess of 35 percent and have significantly improved their turn times. PFC allows clients to focus on their big picture business goals, while skillfully managing all the details. For more information call (800) 493-7063.